The JAMA Legacy

This year we are showcasing what good-quality foreign direct investment looks like across multiple states, including Alabama, Indiana, Kentucky, Ohio and Tennessee. These are just some of the 27 states where Japanese-brand automakers’ manufacturing and other investments have flourished, and their legacies are being written.

Historically, whenever these automakers have entered into communities to provide significant investments, it has involved thoughtful effort to reach out to and partner with community stakeholders. In each instance, the emphasis has been placed on respecting local voices and preserving and enriching the areas which have welcomed these automakers. These are heart-warming stories thanks to Japanese-brand automakers’ consistent financial support and hours of dedication that help strengthen communities. These automakers are active members in the communities surrounding their U.S. facilities with a focus on building roots for the long-term. Because of the way Japanese-brand automakers work, they have naturally become a part of the American landscape.

Marysville, Ohio - 1982 - Honda

Honda’s flagship operations in Ohio encompasses nearly every facet of its business today, which has expanded its manufacturing facilities across the United States. This incredible story started over 40 years ago when the first Honda Accord rolled off the assembly line in 1982.

What began as an automotive plant in a rural Ohio town of only 7,000 people grew significantly to over 27,000 people and the initial investment from Honda served as a catalyst for additional investments as suppliers moved in to help support the new facility. This created even more opportunities for workers in the community and helped establish Honda as a major economic driver in Southwest Ohio.

Honda itself has steadily grown its own local production capabilities and now employs more than 30,000 associates at 18 plants all across the United States producing products from cars, to ATVs, to light jets. In 2021, more than 95% of all U.S.-sold Honda and Acura automobiles were made in North America, using domestic and globally-sourced parts. Cumulatively, Honda has invested nearly $24.6 billion in its North American manufacturing operations, including more than $3.6 billion over the past five years alone.

And while Honda’s economic benefits to the region and the country cannot be overstated, the direct enrichment of the Marysville area can be viewed through another meaningful lens.. Through over four decades of cross-cultural exchange the Japan-America Society of Central Ohio (JASCO) has stood out as one of the most actively engaged chapters of the National Association of Japan-America Societies (NAJAS). In part due to Honda’s strong connections with JASCO, Marysville’s ties to Japanese culture have flourished through the establishment of language-learning schools and the development of many opportunities for people in the area to form genuine friendships.

Honda has also made significant efforts to support local students, recognizing their potential to become the future engineers and leaders that can help uplift the region and the country as a whole as they prepare to design and build not just the vehicles of tomorrow but the vehicles of 50 years from now. Honda’s support in this area has taken many forms over the years through its partnerships with the Center of Science and Industry (COSI) to support STEM education and collaboration with students at Ohio State University on a wide variety of automotive-related research.

Finally, as we look to the present day and the near future, Honda is investing in the long-term future of the region through its new, multibillion dollar investment to make Ohio their “EV Hub.”Through this transformative effort, Honda is actively transforming their Marysville facility to be ready for the next four decades.

Smyrna, Tennessee - 1983 - Nissan

In 1983, when Nissan opened the Smyrna, Tennessee facility the New York Times described Smyrna as a “collection of houses and one-story businesses thrown up in the sun along the Louisville and Nashville railroad tracks.” At the time, Nissan’s investment in the community was the single largest investment by a non-U.S. headquartered automaker in the U.S. and an extremely consequential one for Nissan who has called the state home for over 40 years.

Early media coverage of the facility was filled with unwarranted concern over Japanese business practices and office culture typical in Japan, such as the participation in traditional morning exercises, and whether it would be mandatory for American workers to participate in such activities. But those reports were also filled with a lot of hope for jobs and new opportunities. And in this regard Nissan has certainly delivered.

Since the first white pick up rolled off the assembly line, Nissan has expanded its U.S. footprint to include a powertrain plant in Decherd, Tennessee in 1997 and a vehicle assembly plant in Canton, Mississippi in 2003. Collectively, these facilities have proudly built nearly 20 million vehicles and 13 million engines in the U.S. for customers around the globe.

Nissan’s impact has also extended beyond the factory floor to greater Tennessee. Over the past 40 years, they have consistently demonstrated the priority placed on community engagement. This includes 43,000 volunteer hours by their employees, 38 homes constructed in partnership with Habitat for Humanity, nearly $26M in United Way donation, nearly $2M in education scholarships, and 36,000 pints of blood donated to the American Red Cross.

With Nissan’s presence being felt today more than ever the company is continuing to deepen its commitment to the region through new investments, reskilling, and preparing the next generation of workers. With this kind of dedication Nissan will continue to play a pivotal role in the prosperity and growth of Tennessee for many more years to come.

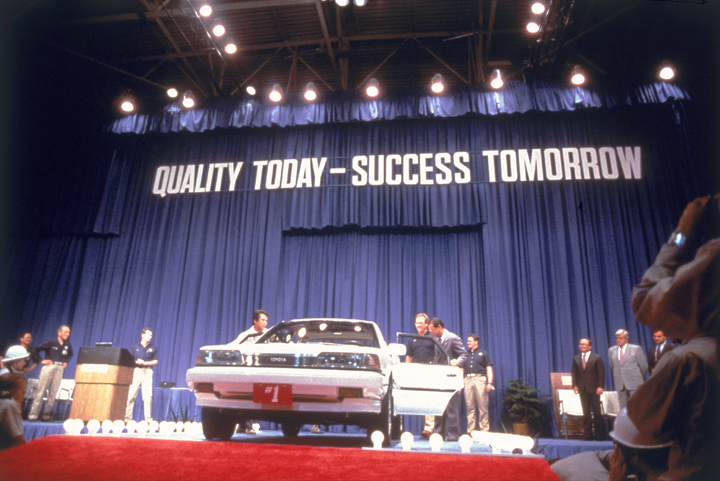

Georgetown, Kentucky - 1988 - Toyota

Toyota Motor Manufacturing, Kentucky (TMMK) stands out globally as the company’s largest vehicle manufacturing plant in the world. This is significant and no small feat. One of the largest auto manufacturers in the world has a facility capable of producing 550,000 vehicles and more than 600,000 engines annually located in the middle of horse country in Georgetown, Kentucky. Since starting production in 1988 when the facility produced its first of many Toyota Camrys, they have now manufactured more than 13 million vehicles in Kentucky, as well as millions of four-cylinder and V-6 engines.

When that first Toyota came off the line, a former president of Toyota Motor Manufacturing, remarked, “Let us not forget the support we have received as we recognize this accomplishment — the Commonwealth of Kentucky, the people of this community and our suppliers all who have contributed to this car.”

Recognizing the importance of the community to their success, Toyota has worked to pay that welcoming spirit forward and since 1986, the company has invested more than $154 million in various philanthropic and educational initiatives, many of which benefit the community around the Georgetown facility. Toyota also works with 400+ different parts and commodities supplier locations in the U.S. with more than 120 of those just in the state of Kentucky. Leading to more jobs and opportunities not only for those in the immediate community, but also in the state and throughout the country.

Over the years, Toyota has also innovated to reduce the overall impact of its operations on the environment. In 2015, Toyota partnered with a local landfill to collect methane gas, a by-product of trash decomposition, and convert it into energy. TMMK’s on-site generator converts collected methane into energy, which is then fed to the plant via a 6.5-mile underground line. In addition, to support water conservation efforts, TMMK uses recycled water for many of its manufacturing processes. The plant receives over 1 million gallons of water each day, cleans it at on-site processing plants, uses it in various processes, cleans it once more and routes it back to the local water utility.

There is truly so much more to note, millions of investments in local schools, partnerships with local community colleges and the pride in being the first location outside of Japan to have Lexus production. The importance of Georgetown, both the facility and the people, to Toyota cannot be overstated. And as the facility approaches its own 40th anniversary in just a few short years, there is sure to be more to come.

Lafayette, Indiana - 1989 - Subaru

In 2022, Subaru of Indiana Automotive (SIA) celebrated its 35th anniversary and subsequently produced its 5 millionth vehicle. This milestone is the result of a legacy that is multiple decades in the making and a story that Subaru continues to write as it leaves its mark on the local community and Indiana more broadly.

When Subaru and Isuzu initially chose the Lafayette area as their new home there were many questions from the local community about whether or not the facility would survive as neither automaker was a household name in the U.S. at the time. But even as the facility and its workers faced challenges and changes, they have persisted and flourished. Today, as Subaru’s only facility outside of Japan, SIA boasts over 6,700 employees, exclusively producing Subaru vehicles nearly around the clock mostly for the North American market, and represents an investment of almost $3 billion in the state of Indiana.

While these numbers are impressive, the initial investment in 1989 proved to be much more consequential to Indiana than a single automotive facility. The decision to open a facility in Indiana has been credited with starting an economic revival in the state and kickstarting a now long standing relationship between the state of Indiana and Japanese industry. Since 1989,billions of dollars have flowed into the state from Japan-based companies, many of which are automotive and include facilities from Honda and Toyota. The relationship is so strong in fact that Japan is perennially Indiana’s top foreign investment and trading partner.

But this kind of good-quality FDI is only possible with local buy-in, a dedicated and engaged workforce, and a strong sense of community and the loyalty of employees, all things Subaru stands for and continues to foster. The SIA Foundation annually supports numerous local charities with thousands of dollars in grant money. The facility itself is the first zero landfill automotive facility in the country and has become a model for many others. The company also regularly engages the local community through educational programs, charity drives, and other programming.

All these efforts demonstrate that Subaru is clearly in it for the long-haul. For its workers, and for their community, SIA is not just looking to be a good neighbor but a focal point of growth, support, and positive change in the greater Lafayette area.

Huntsville, Alabama - 2021 - Mazda-Toyota Manufacturing

In 2018, two of JAMA’s members joined forces to help propel the legacy of Japanese-brand automakers forward. When Mazda and Toyota chose the Huntsville, Alabama, area for their new manufacturing facility they were looking to make a commitment that would be a centerpiece of the community for years to come. For the locals in Huntsville, this new facility also represented a new opportunity for workers in an area of the country that is growing and is increasingly important for the automotive supply chain.

Construction began in 2019 and starting in 2021, the very first Toyota Corolla Cross left the assembly line. Since then, the facility has also begun producing the Corolla Cross Hybrid-Electric Vehicle (HEV) and the Mazda CX-50. In 2023, the facility produced over 150,000 vehicles. All told the companies have invested a combined $2.31 billion in the facility and now employ over 4,500 hard-working Americans.

But the work is not just on the factory floor, it’s also out in the community where Mazda-Toyota continually looks to make an impact.

In 2022, the company opened its doors for a community appreciation event. As part of the event, the Mazda-Toyota team provided tours to assembled guests, highlighting the state-of the art auto facility. The companies also handed out a number of grants through their partnership with the Community Foundation of Greater Huntsville totalling over $180,000 as part of this event. The grants went to organizations that serve the local community through education, economic impact and quality of life programming. Awardees for this first round of grants included Huntsville Hospital Foundation, Drake State Technical College, Limestone County Career Technical Center, Madison City Schools, Athens State University Foundation, the Cap and Gown Project, and KTECH. Many of these partnerships have continued and the Mazda-Toyota Manufacturing grant fund in 2023, awarded an additional $150,000 to local organizations.

As an ongoing legacy, when our members invest in U.S. manufacturing, they lead with their commitment to the success of local communities. Whether it’s through supporting STEM/STEAM education, workforce training, or sponsoring a local event, these are the ways Japanese-brand automakers make their impact known in ways both big and small. Mazda-Toyota Manufacturing is just the latest in a long legacy of this commitment and one we’re looking forward to highlighting all the great things still be to realized.